Home page Description:

An in-house manufacturing facility that can bring your research equipment designs to life.

Posted On: January 23, 2023

Image Caption:

(L-R) Jason Ellis, Mechanical Engineering Technologist; Matthew Filleti, Machine Shop Supervisor; and Ted Clark, Medical Engineering Technologist.

Welcome to UHN’s Machine Shop. Located at Princess Margaret Cancer Centre, the shop is fully equipped for the design and manufacture of medical devices and custom research equipment. Whether you need to design from scratch or are ready to build, the Machine Shop offers the space, infrastructure and expertise to do it.

Supervised by Matthew Filleti, the shared facility is part of the Department of Medical Physics' Radiation Medicine Program. Their services are offered to all UHN employees and external users at a very competitive rate compared to outside facilities. As well, Machine Shop services are half-price for all researchers with a UHN financial account (i.e., a functional cost centre (FCC) number).

Specialized equipment at the Machine Shop includes the following:

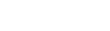

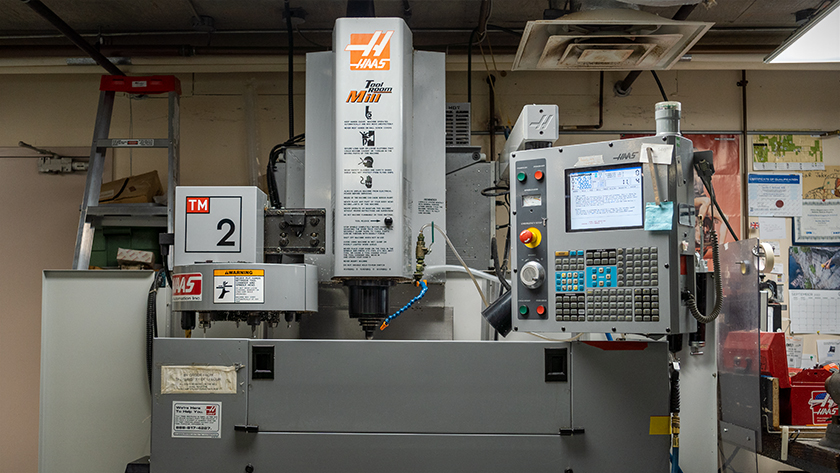

Computer numerical controlled (CNC) milling and lathe

Commonly used in manufacturing machining metal and plastic parts, CNC milling is a method for automating the control of machine tools using software embedded in a microcomputer attached to the tool.

Haas TM-2 CNC Vertical Toolroom Mill, 3-Axis, Bed Type.

Haas SL-10, big bore CNC lathe.

Conventional machine shop tools

These include commonly used equipment such as a lathe, vertical milling machine, horizontal milling machine, drill press, arbor press, band saw, table saw, miter saw, etc.

Holke F-11-V vertical milling machine.

3D Fused Deposition Modeling (FDM) printer from Stratasys

A 3D printing technology that enables you to build strong, durable and dimensionally stable parts with high accuracy. The parts are manufactured by selectively depositing melted material layer-by-layer in a path defined by the computer-aided design (CAD) model.

Ultimaker 5S 3D Printer.

Tungsten inert gas (TIG), metal inert gas (MIG) and ARC welding

These machines allow you to fuse two or more parts of metallic or thermoplastic materials together by means of heat, pressure or both.

Sheet metal tools

A collection of shearing machines that enable you to shape various sheet materials made of copper, zinc, aluminum or steel.

Tennsmith T52 shear and Sampson TBB-1325F break.

SOLIDWORKS and Mastercam CAD software

These programs are commonly used for computer-aided design and engineering; other design software can also be accommodated.

Case study

A thermoforming tool that can be used to prepare brachytherapy treatment equipment.

All components of the device, which works in a similar manner to a panini press, were manufactured at the Machine Shop. The device opens to reveal two black plates: one on top and one on the bottom. The plates are grooved to accept a straight plastic tube. The plates are precisely heated to a temperature that will not melt the plastic tubes but soften them so that they take the shape of the curved grooves. Once formed these tubes are used for brachytherapy in the RMP department.

Do you have a project in mind? Head to the Machine Shop at 610 University Ave, room 12-606, or contact mshop@rmp.uhn.ca or 416 946-4501 x 5194 to request a quote. UHN projects are charged to an approved functional cost centre, while all other projects are invoiced.